Explore More About Manufacturing Execution System

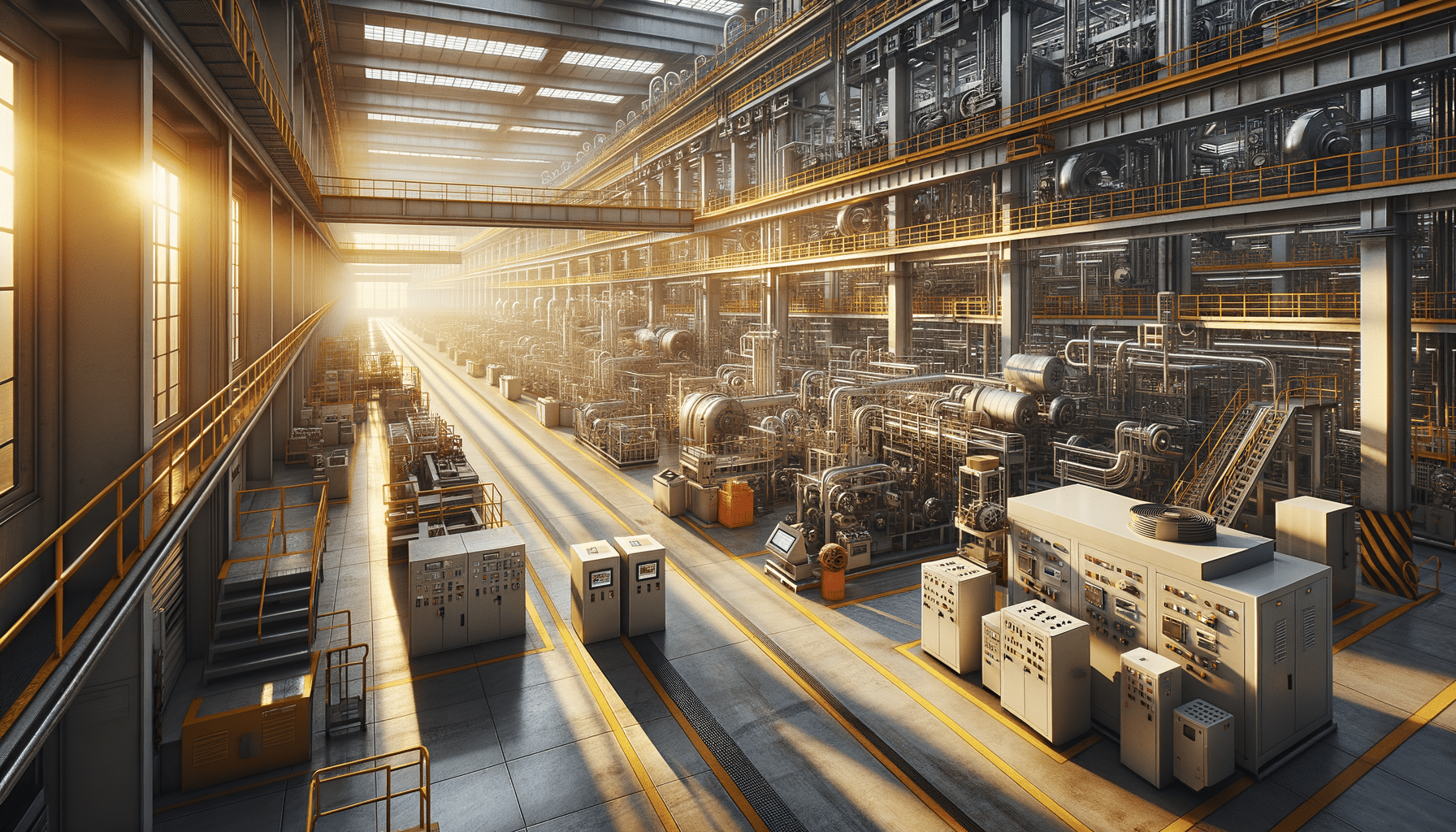

Understanding Manufacturing Execution Systems (MES)

A Manufacturing Execution System (MES) plays a critical role in modern manufacturing by providing real-time insights into production processes. It bridges the gap between enterprise resource planning (ERP) systems and the shop floor, ensuring that production operations are aligned with business objectives. MES offers capabilities such as tracking and monitoring of materials, managing production schedules, and maintaining product quality throughout all stages of manufacturing. By integrating MES with ERP software, manufacturers can achieve seamless data flow between operations and business management, enhancing efficiency and decision-making.

MES systems are designed to capture data directly from machines and workers on the shop floor. This data is then used to provide a comprehensive view of production activities, allowing for better management of resources and quicker response times to any issues that may arise. Some key features of MES include:

- Real-time production monitoring

- Quality management and control

- Production scheduling and planning

- Inventory management

- Performance analysis and reporting

Overall, MES is essential for manufacturers looking to optimize their production processes, reduce waste, and improve product quality.

The Role of ERP Software in Manufacturing

Enterprise Resource Planning (ERP) software is a comprehensive solution that helps organizations manage and integrate various business functions. In the manufacturing sector, ERP systems are crucial for coordinating processes such as procurement, production planning, inventory management, and financial accounting. By centralizing data and providing a unified view of operations, ERP software enables manufacturers to streamline their workflows and improve efficiency.

One of the primary benefits of ERP software is its ability to integrate with other systems, such as MES. This integration facilitates the seamless exchange of data between the shop floor and business management, ensuring that production activities align with organizational goals. ERP software offers a range of features, including:

- Supply chain management

- Financial management and reporting

- Human resources management

- Customer relationship management

- Project management

By implementing ERP software, manufacturers can gain better control over their operations, reduce costs, and enhance customer satisfaction.

Integrating MES and ERP for Enhanced Manufacturing Efficiency

The integration of Manufacturing Execution Systems (MES) with Enterprise Resource Planning (ERP) software is a strategic move for manufacturers aiming to achieve greater operational efficiency. This integration bridges the gap between the shop floor and business management, providing a holistic view of production processes and enabling more informed decision-making.

When MES and ERP systems are combined, manufacturers benefit from:

- Real-time data exchange: Ensures that production data is immediately available for analysis and decision-making.

- Improved resource management: Enables better allocation of materials, labor, and equipment, reducing waste and enhancing productivity.

- Enhanced quality control: Facilitates the monitoring of production quality, leading to higher product standards and customer satisfaction.

- Streamlined operations: Reduces manual data entry and minimizes errors, resulting in more efficient workflows.

By leveraging the strengths of both MES and ERP systems, manufacturers can create a smarter, more agile production environment that is better equipped to meet the demands of today’s competitive market.

Key Benefits of MES and ERP Integration

The integration of Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP) software offers numerous advantages for manufacturers seeking to optimize their operations. Some of the key benefits include:

- Increased visibility: Provides a unified view of production processes and business operations, enabling more strategic planning and decision-making.

- Enhanced collaboration: Facilitates communication and collaboration between different departments, leading to improved coordination and efficiency.

- Reduced lead times: Streamlines production processes and reduces the time required to bring products to market.

- Cost savings: Minimizes waste and inefficiencies, resulting in lower operational costs and improved profitability.

- Scalability: Supports business growth by providing the flexibility to adapt to changing market conditions and customer demands.

Overall, the integration of MES and ERP systems empowers manufacturers to achieve greater control over their operations, improve product quality, and enhance customer satisfaction.

Future Trends in MES and ERP Integration

As technology continues to advance, the integration of Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP) software is expected to evolve, offering even more opportunities for manufacturers to enhance their operations. Some of the trends shaping the future of MES and ERP integration include:

- Increased use of artificial intelligence and machine learning: These technologies will enable more advanced data analysis and predictive insights, leading to smarter decision-making and improved efficiency.

- Greater emphasis on cloud-based solutions: Cloud-based MES and ERP systems offer greater flexibility, scalability, and accessibility, allowing manufacturers to manage their operations from anywhere.

- Enhanced focus on sustainability: As environmental concerns continue to grow, manufacturers will increasingly seek to integrate MES and ERP systems to reduce waste and improve resource management.

- Integration with the Internet of Things (IoT): IoT devices will provide real-time data from the shop floor, enabling more accurate monitoring and control of production processes.

By staying ahead of these trends, manufacturers can ensure that their MES and ERP systems remain at the forefront of innovation, driving continued success in an ever-changing market.