Explore More About Manufacturing Execution Systems

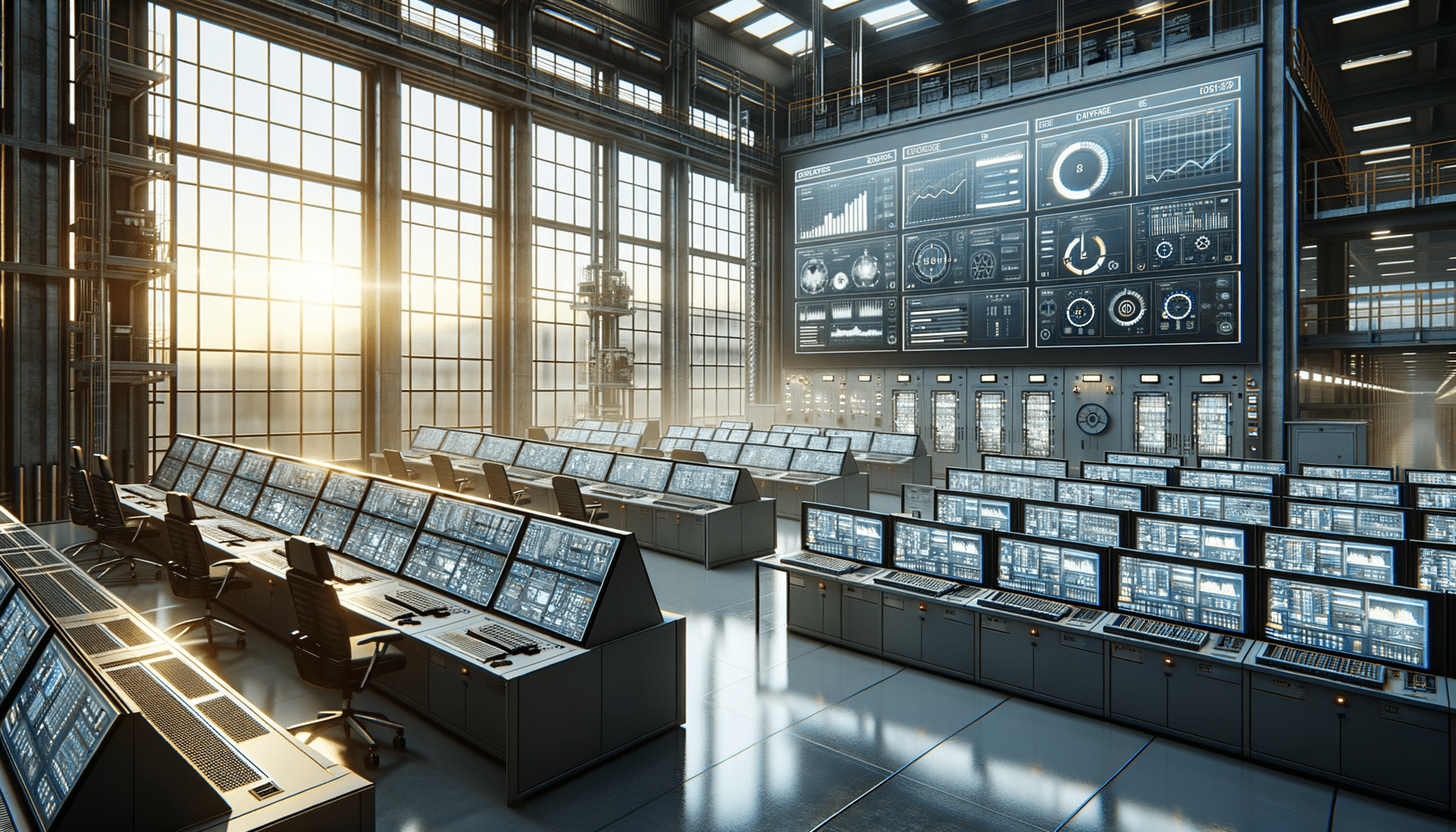

Introduction to Manufacturing Execution Systems

In the dynamic world of manufacturing, efficiency and precision are crucial. A Manufacturing Execution System (MES) stands at the intersection of production processes and business management, acting as a bridge to ensure seamless operations. MES is designed to track and document the transformation of raw materials into finished goods in real-time. By doing so, it not only enhances productivity but also maintains quality standards across the production line. The integration of MES with ERP (Enterprise Resource Planning) systems creates a unified platform that facilitates strategic decision-making by providing real-time insights from the shop floor to the management suite. This connection ensures that every decision is informed by accurate, up-to-date data, leading to improved overall efficiency.

The Role of MES in Modern Manufacturing

Manufacturing Execution Systems are instrumental in modern manufacturing environments. They provide a comprehensive view of production activities, allowing managers to make informed decisions. MES systems offer functionalities such as scheduling, resource allocation, and production analysis. These components are vital for optimizing manufacturing processes. For instance, MES can track equipment usage and downtime, providing valuable data that can be used to improve machine maintenance schedules and reduce unexpected breakdowns. Additionally, MES systems support compliance with industry standards by ensuring that every step of the production process adheres to predefined quality criteria. This capability is crucial in industries where regulatory compliance is mandatory, such as pharmaceuticals and aerospace.

Integration of MES with ERP Systems

The integration of MES with ERP systems is a strategic move that many manufacturers are adopting. This integration provides a seamless flow of information from the factory floor to the management level, enhancing visibility and control over the entire production process. An integrated system allows for better resource management, as data from MES can be used to optimize inventory levels and reduce waste. Furthermore, it supports real-time decision-making by providing managers with immediate access to critical production data. This capability is particularly valuable in fast-paced manufacturing environments where quick responses are essential to maintaining competitive advantage.

Benefits of Implementing MES

Implementing a Manufacturing Execution System offers numerous benefits that can transform production operations. One of the primary advantages is enhanced production efficiency. By providing real-time data, MES systems enable manufacturers to identify bottlenecks and streamline processes. This leads to reduced cycle times and improved throughput. Additionally, MES systems contribute to quality assurance by monitoring production parameters and ensuring that products meet specified standards. This capability reduces the risk of defects and enhances customer satisfaction. Other benefits include improved traceability, which is essential for meeting regulatory requirements and managing recalls effectively.

Future Trends in MES Technology

The evolution of MES technology continues to shape the future of manufacturing. As industries move towards smart manufacturing, MES systems are becoming more sophisticated, incorporating advanced technologies such as IoT (Internet of Things) and AI (Artificial Intelligence). These technologies enhance the capabilities of MES systems by providing predictive analytics and enabling proactive maintenance strategies. Moreover, the rise of cloud-based MES solutions offers scalability and flexibility, allowing manufacturers to adapt to changing market demands. As these trends continue to develop, MES systems will play an increasingly critical role in driving innovation and competitiveness in the manufacturing sector.